- PE bubble film making machine

- – FTPEI-1200-1300 Bubble film machine (one extruder) 2 layer film

- – FTPEI-1500-1600 PE bubble film machine (one extruder) 2 layer

- – FTPEG-1500,1600 Polyethylene Bubble Film Machine

- – FTQB-600-1200 Bubble Film Bag Making Machine(with folder)

- – FTPE-600-2500 Bubble film making machine (one extruder) 2layer film

- Stretch film making machine

- – FT-500-800 Single Layer Stretch Film Machine (normal)

- – FT-500-800 Single Layer Stretch Film Machine (auto cutter)

- – FT-1000-1200 single layer stretch film machine (normal)

- – FT-1000-1200 single layer stretch film machine (auto cutter)

- – FT-500-1500 Double Layer Co-extrusion Stretch Film Making Machine (Auto Changer)

- – FTRW Series Stretch Film Rewinding Slitter

- – 500mm Automatic stretch film rewing machine

- – FTP-300 high-speed automatic cling film rewinder

- – Full Automatic Full Biodegradable High Speed Bag Making Machine

- Printing machine

- Film Blowing Machine

- – SJ-A50/55/65/65-1 PE High & low-pressure Film Blowing Machine

- – SJ-B RRotary Die Film Blowing Machine(PE Heat-shrinkable Film Blowing Machine)

- – SJ-C75/90/105/120 High Speed Film Blowing Machine

- – SJ-D Mini Film Blowing Machine

- – SJ-D50/55 Mini Film Blowing Machine

- – SJ Double Color Film Blowing Machine

- – SJ-FM Double Die Head Film Blowing Machine

- – SJ-PP Film Blowing Machine

- Machine Associated Equipment

- – FTV Vertical Mixer

- – FT-300GN Auto Loader

- – FT-700GN Split Style Auto Loader

- – Plastic Dryer

- – FT-AC industrail chiller(air cooled)

- – Plstic Grinder

- – X625 Hydraulic Pressure Punching Machine

- – X626 Hydraulic Pressure Punching Machine

- – Waste Film Collection Device

- – Corona Treater

- – Soft Handle Sealing Machine

- Bag Making Machine

- Slitting and Rewinding Machine

- Recycling Machine

- Zipper Machine

- On Line Service

Print this page

Print this page Bookmark this

Bookmark this  Inquiry

Inquiry E-mail Us

E-mail Us Live Messenger

Live Messenger PDF Download

PDF Download

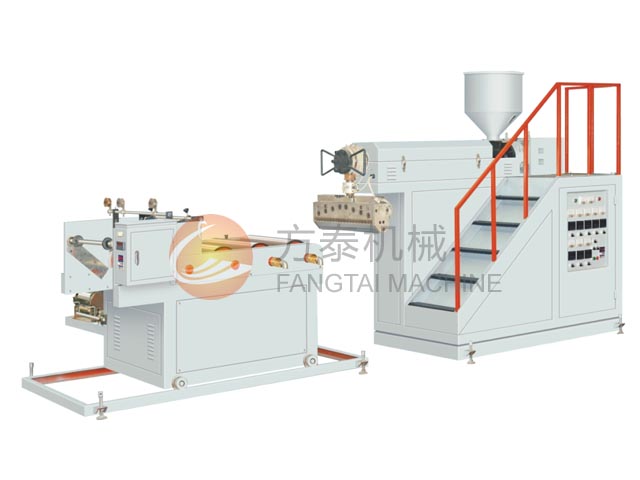

FT-500-800 Single layer stretch film machine / cling film machine

This machine can produce stretch film or cling film

Use

stretch film machine / cling film machine uses LLDPE as main material and adopts several kinds of resins to manufacture the double-side self-sticky or double side non-sticky stretch wrapping film. The film has good tensile strength, anti-pricking ability and impact strength. Its good shrinking memory function and self-sticky can make goods integrity to prevent goods from loosening and collapsing during transportation and being polluted by dust. The transparency and tensile strength of this product can make the packaging beautiful, economical and practical. The film can be widely used in wrapping of palletized goods. It’s a good substitute for hot shrinking packaging film during transportation.

Characteristics

1.Screw and cylinder are all made of 38 CrMoALA with nitrogen treatment, which has an advantage of corrosion resistance and endurance, etc.

2.The cooling device adopts cycle water cooling which provide the best transparent effect of the stretch film

3.Rewinder adopts with friction-rewinding-type, with cutter device for edge correcting.

OPTIONAL EQUIPMENT

1)AUTO LOADER 2)AIR SHAFT 3)AUTO DRY HOPPER 4)ELECTRIC CHANGE 5)HYDRAULIC NET CHANGER 6) GLUE PUMP

7) AUTO CHANGER, AUTO CUTTER (SIMENS PLC CONTROLLER)

Main technical parameters

|

Model |

FT-500 single-layer |

FT-600 single-layer |

FT-800 single-layer |

|

Diameter of Screw Stem |

φ55 mm |

φ55 mm |

φ65 mm |

|

L/D Ratio of Screw |

28:1 |

28:1 |

28:1 |

|

Material of Scerw & Barrel |

38 CrMoALA |

38 CrMoALA |

38 CrMoALA |

|

Rationl Speed of Screw Stem |

10-120 rpm |

10-120 rpm |

10-120 rpm |

|

Width of T-die |

650 mm |

750 mm |

950 mm |

|

Heating Way |

Casting-aluminum heating device |

Casting-aluminum heating device |

Casting-aluminum heating device |

|

Width of Traction Roller |

650 mm |

750 mm |

950 mm |

|

Folding Width of Products |

200-500 mm |

200-600 mm |

200-800 mm |

|

Thickness |

0.015-0.05 mm |

0.015-0.05 mm |

0.015-0.05 mm |

|

Main Motor |

15 kw |

15 kw |

18.5 kw |

|

Heating Power |

18 kw |

18 kw |

22 kw |

|

Tractiong Motor |

2.2 kw |

2.2 kw |

3 kw |

|

Max. Output(kg/h) |

40 |

50 |

90 |

|

Machine Weight |

2.2T |

2.2T |

3.5T |

|

Overall Dimensions (L*W*H) |

4500 mm*2100 mm*2550 mm |

4600 mm*2200 mm*2600 mm |

7000 mm*4000 mm*3000 mm |

0086-577-66870896

0086-577-66870896