- PE bubble film making machine

- – FTPEI-1200-1300 Bubble film machine (one extruder) 2 layer film

- – FTPEI-1500-1600 PE bubble film machine (one extruder) 2 layer

- – FTPEG-1500,1600 Polyethylene Bubble Film Machine

- – FTQB-600-1200 Bubble Film Bag Making Machine(with folder)

- – FTPE-600-2500 Bubble film making machine (one extruder) 2layer film

- Stretch film making machine

- – FT-500-800 Single Layer Stretch Film Machine (normal)

- – FT-500-800 Single Layer Stretch Film Machine (auto cutter)

- – FT-1000-1200 single layer stretch film machine (normal)

- – FT-1000-1200 single layer stretch film machine (auto cutter)

- – FT-500-1500 Double Layer Co-extrusion Stretch Film Making Machine (Auto Changer)

- – FTRW Series Stretch Film Rewinding Slitter

- – 500mm Automatic stretch film rewing machine

- – FTP-300 high-speed automatic cling film rewinder

- – Full Automatic Full Biodegradable High Speed Bag Making Machine

- Printing machine

- Film Blowing Machine

- – SJ-A50/55/65/65-1 PE High & low-pressure Film Blowing Machine

- – SJ-B RRotary Die Film Blowing Machine(PE Heat-shrinkable Film Blowing Machine)

- – SJ-C75/90/105/120 High Speed Film Blowing Machine

- – SJ-D Mini Film Blowing Machine

- – SJ-D50/55 Mini Film Blowing Machine

- – SJ Double Color Film Blowing Machine

- – SJ-FM Double Die Head Film Blowing Machine

- – SJ-PP Film Blowing Machine

- Machine Associated Equipment

- – FTV Vertical Mixer

- – FT-300GN Auto Loader

- – FT-700GN Split Style Auto Loader

- – Plastic Dryer

- – FT-AC industrail chiller(air cooled)

- – Plstic Grinder

- – X625 Hydraulic Pressure Punching Machine

- – X626 Hydraulic Pressure Punching Machine

- – Waste Film Collection Device

- – Corona Treater

- – Soft Handle Sealing Machine

- Bag Making Machine

- Slitting and Rewinding Machine

- Recycling Machine

- Zipper Machine

- On Line Service

Print this page

Print this page Bookmark this

Bookmark this  Inquiry

Inquiry E-mail Us

E-mail Us Live Messenger

Live Messenger PDF Download

PDF Download

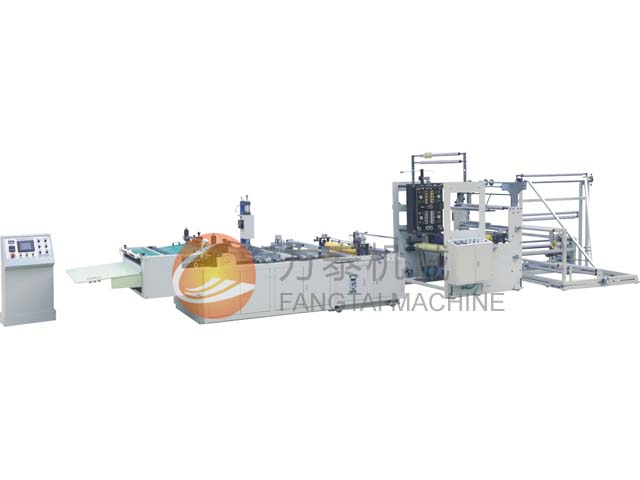

Performance and Characteristics:

1. This machine uses fully automatic servo motor with computer digital function to control length, it is easy for operation. The produced one is very tight and fast at the seals, it apparently shows a good quality.

2. Flow process of production is from rolled material through automatic edge alignment, edge trimming, strip piercing, laminating, ultrasonic compressive embossing, photo cell sensing, hole punching, thermo cutting off and ends with automatic counting, all of the operations are fully automatic.

3. This machine equips automatic stop equipment, it will work to stop the machine when it is running out of material supply or when photo cell is out of order or when temperature is losing down and below the minimum required.

Main Technical Variables

|

Machine model |

TPM-600 |

TPM-800 |

|

Material |

LDPE-PP-PPE |

LDPE-PP-PPE |

|

Capacity |

50~150 (Cycle/min) |

50~130 (Cycle/min) |

|

Cutting width |

100~500 mm |

120~600 mm |

|

Cutting length |

120~600 mm |

150~800 mm |

|

Thickness of film |

0.04~0.15 mm |

0.04~0.15 mm |

|

Film annulus diameter |

φ500×1200 mm |

φ500×1600 mm |

|

Step motor |

1kw |

1kw |

|

Transducer motor |

1.5kw |

2.2kw |

|

Heater |

3kw |

3.5kw |

|

Food-out motor |

0.25kw |

0.37kw |

|

Ultrasonic |

1set |

1set |

|

Conveying electrical |

0.55kw |

0.75kw |

|

Food film motor |

0.55kw |

0.75kw |

|

Sealing capacity |

10-30m/min |

10-30m/min |

|

Cooling |

0.37kw |

0.37kw |

|

Power |

15kw |

17kw |

|

Overall dimension (L×W×H)mm |

8500×1800×1800 |

8650×1900×1800 |

|

Voltage |

50Hz 220v |

50Hz 220v |

|

Press empty machine |

1900×1850×1700 |

2100×1850×1700 |

|

Packing dimension (L×W×H)mm |

1700×1500×1900 |

1900×1500×1900 |

0086-577-66870896

0086-577-66870896