- PE bubble film making machine

- – FTPEI-1200-1300 Bubble film machine (one extruder) 2 layer film

- – FTPEI-1500-1600 PE bubble film machine (one extruder) 2 layer

- – FTPEG-1500,1600 Polyethylene Bubble Film Machine

- – FTQB-600-1200 Bubble Film Bag Making Machine(with folder)

- – FTPE-600-2500 Bubble film making machine (one extruder) 2layer film

- Stretch film making machine

- – FT-500-800 Single Layer Stretch Film Machine (normal)

- – FT-500-800 Single Layer Stretch Film Machine (auto cutter)

- – FT-1000-1200 single layer stretch film machine (normal)

- – FT-1000-1200 single layer stretch film machine (auto cutter)

- – FT-500-1500 Double Layer Co-extrusion Stretch Film Making Machine (Auto Changer)

- – FTRW Series Stretch Film Rewinding Slitter

- – 500mm Automatic stretch film rewing machine

- – FTP-300 high-speed automatic cling film rewinder

- – Full Automatic Full Biodegradable High Speed Bag Making Machine

- Printing machine

- Film Blowing Machine

- – SJ-A50/55/65/65-1 PE High & low-pressure Film Blowing Machine

- – SJ-B RRotary Die Film Blowing Machine(PE Heat-shrinkable Film Blowing Machine)

- – SJ-C75/90/105/120 High Speed Film Blowing Machine

- – SJ-D Mini Film Blowing Machine

- – SJ-D50/55 Mini Film Blowing Machine

- – SJ Double Color Film Blowing Machine

- – SJ-FM Double Die Head Film Blowing Machine

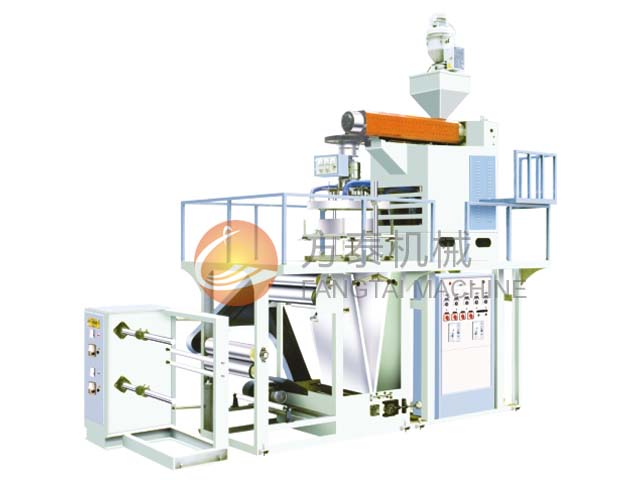

- – SJ-PP Film Blowing Machine

- Machine Associated Equipment

- – FTV Vertical Mixer

- – FT-300GN Auto Loader

- – FT-700GN Split Style Auto Loader

- – Plastic Dryer

- – FT-AC industrail chiller(air cooled)

- – Plstic Grinder

- – X625 Hydraulic Pressure Punching Machine

- – X626 Hydraulic Pressure Punching Machine

- – Waste Film Collection Device

- – Corona Treater

- – Soft Handle Sealing Machine

- Bag Making Machine

- Slitting and Rewinding Machine

- Recycling Machine

- Zipper Machine

- On Line Service

Print this page

Print this page Bookmark this

Bookmark this  Inquiry

Inquiry E-mail Us

E-mail Us Live Messenger

Live Messenger PDF Download

PDF Download

1.This screw material cylinder is elabroately made of 38CRMOALA alloy steel after nitrogen treatment and has best rigidity and corrosion resistance.

2.The mould head is plated with hard chroming and has screw mandrel structure with uniform and smooth material discharing. And the aircooled device has labyrinth lype structure with characteristic as uniform air-jut quantity , automatic temperature control and automatic heating.

OPTIONAL EQUIPMENT

1) AUTO LOADER

2) FILM SURFACE TREATER

3) DIE ROTARY DEVICE

4) AIR COMPRESSOR

Main Technical Variables:

|

Type |

SJPP-55 |

SJPP-60 |

SJPP-70 |

|

Diameter of screw |

Φ55 |

Φ60 |

Φ70 |

|

L/D |

28:1 |

28:1 |

28:1 |

|

Folding width of film(mm) |

100-500 |

100-600 |

300-800 |

|

Single-face Thickness of film(mm) |

0.01-0.1 |

0.01-0.1 |

0.01-0.1 |

|

Max. Extrusion(kg/h) |

30 |

45 |

60 |

|

Power of main motor(kw) |

11 |

15 |

18.5 |

|

Power of Traction motor(kw) |

1.1 |

1.1 |

1.5 |

|

Length of Traction roller(mm) |

550 |

650 |

850 |

|

Outline diameter(L×W×H) |

4500×2000×4200 |

4800×2500×4500 |

5000×2800×5000 |

|

Weight(T) |

3 |

4 |

5 |

0086-577-66870896

0086-577-66870896