- On Line Service

Print this page

Print this page Bookmark this

Bookmark this  Inquiry

Inquiry E-mail Us

E-mail Us Live Messenger

Live Messenger PDF Download

PDF Download

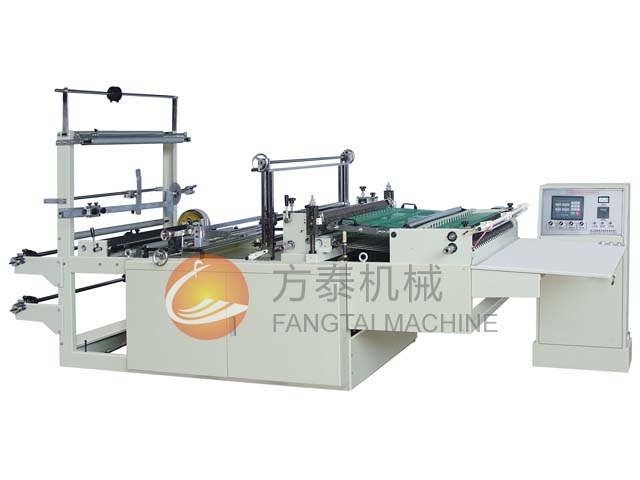

This machine is used to make bags for garment, sock, bread, ornaments, stationery, electricity elements and so on.

Use

This machine is suitable for the manufacture clothing bagging, the sock bag, the towel bag, the bread bag,the accessories bag, Underwear bag, the article of stationery bag, the electric appliance part bag, Thin film bag and so on.

Processed The Material:

BOPP、 PP、 PE, the hot contraction membrane and so on each kind may the heat bondingmaterial.

The Function and Characteristic:

1. the complete machine use the microcomputer computer control, step-by-steps the electrical machinery to tow the material (to be possible to choose and match servomotor control system).

2. computer fixed-length, the length of stride electro-optic track, is accurate, is steady, throws the sign auto-stop, the feeding uses the photoelectric control.

3. The automatic computation and to assigns quantity warning.

4. Heat-sealing fancy borders in printing; automatic punching(hanging holes and exhausting holes); automatic gluing.

5. cylinder brokage, feeding rectify, hole rectify(it is necessary to add device.)

Main Technical Parameters:

|

Model |

RFQ-400 |

RFQ-500 |

RFQ-600 |

RFQ-700 |

RFQ-800 |

RQ-900 | ||

|

Length of finished product |

30-400 |

30-500 |

60-600 |

70-700 |

80-800 |

90-900 | ||

|

Width of finished product |

25-500 |

45-600 |

50-600 |

50-600 |

55-600 |

60-600 | ||

|

Speed of Bag-making |

30-240 | |||||||

|

Accuracy of finished product |

±0.3 | |||||||

|

Total power |

3.5 |

3.5 |

4 |

4.5 |

5 |

6 | ||

|

Weight |

600 |

700 |

800 |

900 |

1000 |

1100 | ||

|

Overall dimension (mm) |

L |

3500 |

3500 |

3500 |

3500 |

4000 |

4000 | |

|

W |

900 |

1000 |

1100 |

1200 |

1300 |

1400 | ||

|

H |

1300 |

1300 |

1300 |

1300 |

1300 |

1300 | ||

| Subject: | |

| *Name: (Contact Pers_proon) |

|

| *Business Email: | |

| Company Name: | |

| Website: | |

| *Business Phone: | |

| Business Fax: | |

| *Message: | |

| Know Us From: | |

0086-577-66870896

0086-577-66870896